Comprehensiveness of Ultramodula services - from design to implementation

Every successful entrepreneur is an expert in their field, but not everyone has to be an expert in the subject construction or management of investment projects. There is no doubt, however, that every company at some point in its development will need its own headquarters, whether on office, warehouse, shop or premises service. Nowadays, when business development goes hand in hand with the growing need for mobility, all kinds of buildings and pavilions containers are becoming an increasingly popular alternative. Ultramodula is a company that specializes in the production of this type of objects. But its offer is much more. Read the article and learn about the comprehensiveness of Ultramodula's services - from design to implementation.

Why is it worth choosing a manufacturer that provides comprehensive services?

In short: so you don't have to be an expert in everything. Outsourcing a comprehensive service, i.e. from design to implementation, has many advantages that translate into project success, lower costs and shorter implementation time. The entrepreneur can focus on his business and the contractor will take care of the rest. The key arguments that will convince everyone to choose a comprehensive service:

- convenience and time saving - you do not have to worry about project organization and coordination of activities of various subcontractors;

- greater control over the project - when all stages of the project are carried out by one contractor, it is easier for the investor to control the course of the investment;

- lower costs – in the case of commissioning various stages of the project to different contractors, the costs may be higher than in the case of commissioning all activities to one contractor, because he has better control over the entire investment budget;

- higher quality of project implementation - the contractor responsible for the entire project knows that he must ensure quality at every stage to facilitate his work and minimize the risk of unforeseen costs.

The comprehensiveness of Ultramodula services

What does the comprehensiveness of Ultramodula services mean?

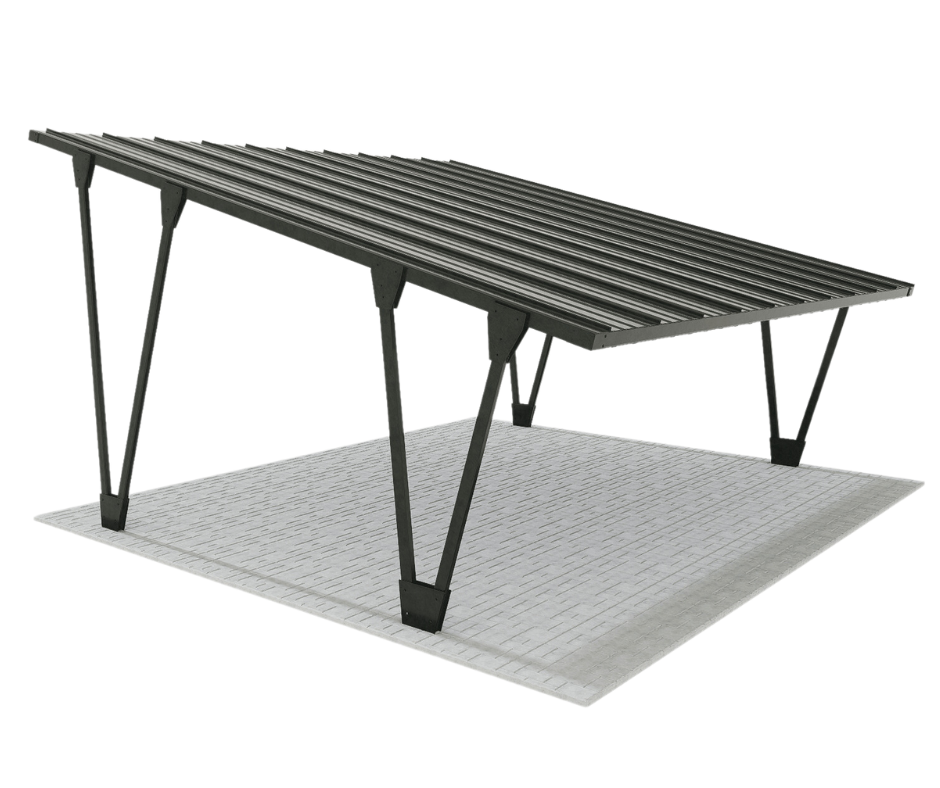

Ultramodula is experienced producer containers i pavilions specializing in the design, production and assembly of these structures. It offers a wide range of products, depending on the customer's needs. The portfolio includes both containers warehouse, office, socialAnd commercial pavilions, catering and even residential and houses modular. As a manufacturer, it can also carry out projects for individual customer orders. Each topic can lead the investor comprehensively - from design to implementation.

First: the design

The first stage of production is designing the facility in accordance with the customer's requirements. Ultramodula offers a wide range of sizes and types of containers, thanks to which you can adjust the project to individual needs. They are on offer office containers, storage, sanitary and hygienic, social or residential. In addition, the manufacturer implements projects of commercial, gastronomic, service and office pavilions. Investors can simply purchase a standard solution, make minor or major modifications, as well as design a facility for individual orders, tailored to their needs.

The entire process: whether changes or designing "from scratch" is supervised by a team of experienced experts, including specialists in electrical, sanitary and heating installations. The project coordinator can also advise on all formalities and help in obtaining the necessary permits or official notifications.

Stage two: production

After the design phase is completed, the next stage is the production of the facility. The high quality of the containers and pavilions produced is mainly due to the controlled production process outside the construction site.

The production of individual objects-modules takes place in carpet Ultramodula production facility with the use of professional equipment, in fully controlled conditions, and, what is extremely important, in compliance with all construction standards. Whole building is performed in an environment with controlled temperature, humidity and no dust, which minimizes the risk of construction irregularities. It is also important that assembling components such as doors or windows in factory conditions allows for greater precision and better quality control. The entire production process is controlled by experienced engineers.

As part of a comprehensive service, facilities made by Ultramodula are equipped with all installations: electricity, water and sewage and heating. Each of their elements is made and assembled in safe factory conditions by experienced professionals. This guarantees the high quality of these components and ensures trouble-free operation for a long time.

The third step, i.e. transport and assembly at the destination

After manufacturing, Ultramodula deals with logistics, i.e. transport and assembly, as in the case of buildings container is a process that requires appropriate preparation and experience. Depending on the project, it may be necessary to use specialized equipment, and each time you need to know in detail the necessary legal regulations and meet the requirements of safety standards. It is worth emphasizing that the transport and assembly of pavilions and containers are key elements in the entire process of their construction and installation.

The transport of objects requires meticulous preparation, e.g. by attaching internal and external elements, securing doors and windows, and ensuring proper stability and balance during transport to the destination. The experience of the Ultramodula team guarantees that this stage of the project will be carried out efficiently and professionally, and most importantly in accordance with the provisions of the road law.

The assembly of container buildings takes place in several stages, including setting the containers in place, connecting them to each other, installing doors and windows and connecting all planned installations.

In the case of small buildings, this is the shortest phase of the entire investment. Container is placed on the foundations using a crane or HDS, and it takes several minutes. When more complex projects are involved, the assembly of container buildings may require the use of specialized tools and equipment, such as cranes or lifting platforms. Then, of course, it lasts a bit longer - up to several or several dozen days.

Cooperation with Ultramodula is a good choice

If you want to quickly and efficiently carry out an investment related to the company's headquarters, it is worth focusing on cooperation with a reputable manufacturer that provides comprehensive services. Ultramodula will professionally lead each project - both for one, small container office or warehouse, as well as for a large multi-module building. An experienced team of experts provides support at every stage of the project.