Modular construction seems to be a very modern solution, with a short history - but this is not entirely true. Yes, the boom of these solutions is related to the strong urbanization trend of the last few decades, but the idea itself and its use are not new. History modular building systems are up to several hundred years old. The first project known among architects building modular there is Renkioi Hospital by Isambard Kingdom Brunel. This facility was built in 1885 entirely of wood. It was a fully functional British Army military hospital for use during the Crimean War. How are modular objects used today and where does their enormous popularity come from? A good way to answer this question is to compare modular building systems with traditional methods.

Modular building systems – what are they?

Defining modular systems construction, they should be viewed as precisely constructed modules that connect with each other to create complex structures. To put it simply, these are blocks that can be used to build any object - the only limitation is human imagination. Unlike traditional methods where building is based on the gradual progress of work on site construction, modular approach allows for the prefabrication of components in controlled factory conditions. This technological leap not only reduces construction time, but also ensures higher construction quality.

The importance of modular building systems in today's world cannot be overstated. Compared to traditional methods, this innovative construction method enables faster, more effective and precise construction of objects. And in the face of dynamic socio-economic and ecological changes, this type of solutions are becoming a key element in adapting the construction industry to new realities. This phenomenon is due to the increased demand for efficient, economical and ecological construction methods.

Modular buildings are an economical solution

One of the key advantages of using modular building systems is their significantly lower cost compared to traditional building materials. Purchase and installation price containers modular construction is significantly lower than any construction using traditional methods. In addition, containers they are easily available and can be quickly transported to the construction site, which effectively shortens the project implementation time and therefore reduces the costs associated with the work of specialists. Another important aspect is the fact that the objects are completely prefabricated in the factory and then transported to the investment site as ready-made elements for assembly. All these factors make the final price of buildings made of containers extremely attractive compared to traditional solutions.

The economics of modular construction also result from the ease of expansion and modification. In the case of traditional construction methods, such as bricklaying, the need to determine the final form of the building from the very beginning forces the investor to choose a durable design. In contrast, modular building systems offer great flexibility, as adding additional modules is not only simple and quick, but also extremely cost-effective.

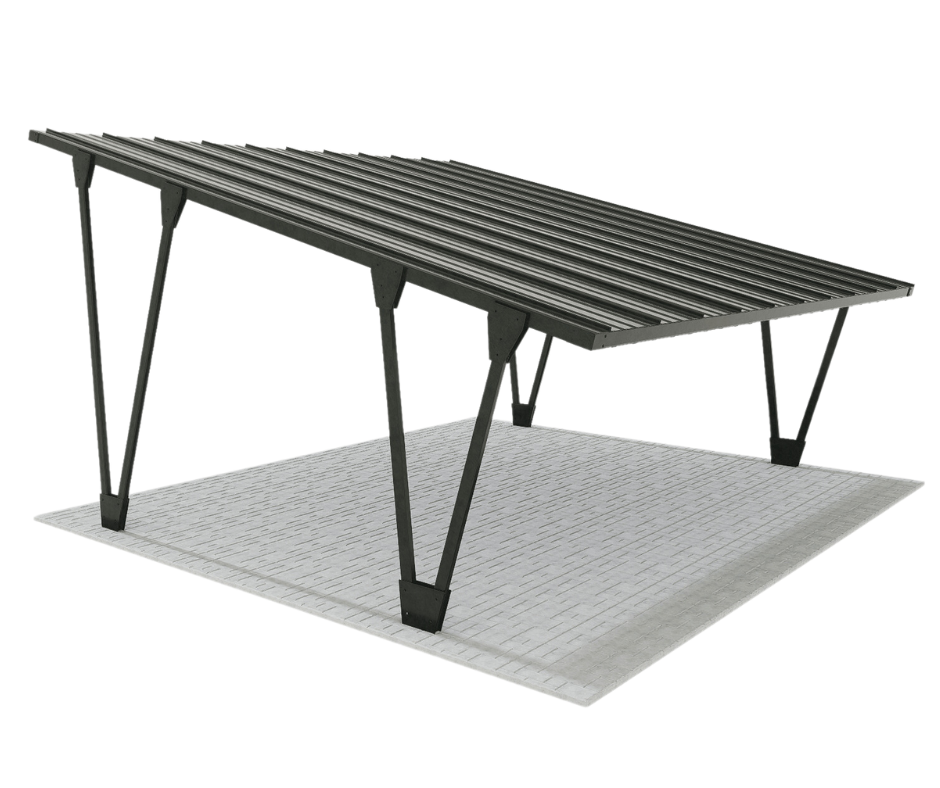

The cottage modular | Ultramodule

Short implementation time of modular buildings

In today's dynamic world, where time has become one of the most valuable resources, every minute matters. In the context of construction, where time is real money, modular building systems bring tangible benefits thanks to the speed and ease of assembly. These features not only translate into lower overall construction costs, but also reduce losses related to the loss of potential benefits, both for enterprises that temporarily suspend their operations for the duration of the investment, and for private individuals who avoid long-term waiting to build their own premises. and incur rental costs during this time.

In practice, building a small residential house or... pavilion commercial using modular building systems is a matter of several weeks, or sometimes even just a few days. Most often, it takes the longest to adapt the functional layout of the interior to the individual needs and expectations of the investor. The "construction" process itself at the target site is really quick, especially when the foundation (made of prefabricated blocks) is prepared and the necessary installations are ready for use. Building containerized, thanks to the use of a crane or a truck with HDS, it can be placed in the indicated place in literally a dozen or so minutes.

Of course, in the case of larger objects consisting of several or even several dozen modules, this process will be correspondingly longer, but still significantly shorter compared to traditional methods, such as building with bricks. The speed and efficiency of assembly also reduce the risk of unexpected costs resulting from delays that often occur during investments carried out using traditional construction methods.

High quality and durability of modular building systems

In recent years, modular construction has gained a very good reputation on the market in terms of quality. Investors and users have realized that modern facilities made of ready-made modules have nothing in common with poor-quality sheet metal structures from several dozen years ago. Modern modular building systems are solutions of much higher quality, which is mainly due to the production process carried out off-site.

Production under controlled conditions

The key element ensuring the quality of modular structures is production under controlled conditions. Individual elements of the facilities are manufactured in production halls under fully monitored conditions, using advanced equipment and in accordance with applicable standards and construction norms. The entire structure is created in an environment with precisely controlled temperature, humidity and dust-free, thus minimizing the risk of errors. Assembly of components such as doors and windows in a factory setting also provides greater precision and better quality control. A significant impact on the quality and durability of modular buildings is the fact that they are delivered to the assembly site fully equipped with all necessary installations: electrical, water, sewage and heating. Each element is carefully made in controlled factory conditions by experienced professionals.

Appropriate design and materials

Another advantage that distinguishes modular objects is their design, which is characterized not only by wide arrangement possibilities, but above all by durability and made of the highest quality materials. This means that buildings based on this technology can be used in commercial, residential and industrial facilities.

Starting from the top, the key element of high-quality modules is the roof. Its solidity is based on the use of durable sheet metal. This type of covering not only ensures durability, but also gives buildings a modern look. Importantly, the sheet is available in various colors from the RAL palette, which allows the project to be tailored to the investor's expectations. Another important element is the appropriate angle of the roof inclination, which allows for free drainage of snow and rain. In the case of modular houses, the most common slope angle is 30%, while in buildings container the roof is almost flat (slope is 2%). Reputable manufacturers guarantee solid roof insulation, which is crucial for effective heating of the building in winter. The optimal design includes an insulating layer of mineral wool with a thickness of 100 to 200 mm, combined with a roof membrane and a vapor barrier foil.

Moving on to the lower part of the structure, the foundation of the strength of the entire facility is the solid welding of steel sections. Cold-formed sections with a thickness of 4 mm are preferred and the columns are screwed to the upper and lower frames. The walls of buildings using modular building systems from renowned manufacturers ensure an effective heat transfer coefficient, which is achieved thanks to the use of mineral wool insulation. This not only guarantees durability, but also effective protection against heat loss, ensuring comfortable conditions residential in every period of the year.

scalability

Modular building systems enable seamless addition of new modules to existing buildings. It is not only convenient, but also an optimal solution that allows you to increase the usable area at any time. Regardless of whether it is a store, restaurant or office, modular containers allow for dynamic adaptation to changing business needs. Importantly, the expansion is not limited only to the width of the area - it is also possible to expand the building upwards. The design of high-quality containers allows for stacking, which further increases the spatial and functional flexibility of modular facilities. Thanks to this flexibility, which buildings built using traditional methods do not have, adapting the space to current needs and market trends is extremely easy and does not generate large costs. Scalability therefore becomes a key factor enabling effective space management and at the same time protecting against future challenges and changes that will undoubtedly come.

Modular building systems – a revolution compared to traditional methods

Nowadays, when the dynamic development of society and economy poses new challenges for us, a revolution in the field of construction is inevitable. Traditional construction methods, although proven and reliable, often fail to keep up with the demands of today's rapidly changing world. In this context, modular building systems, especially in the form of containers, are entering the scene as an innovative solution that not only meets but exceeds expectations in terms of efficiency and economy.